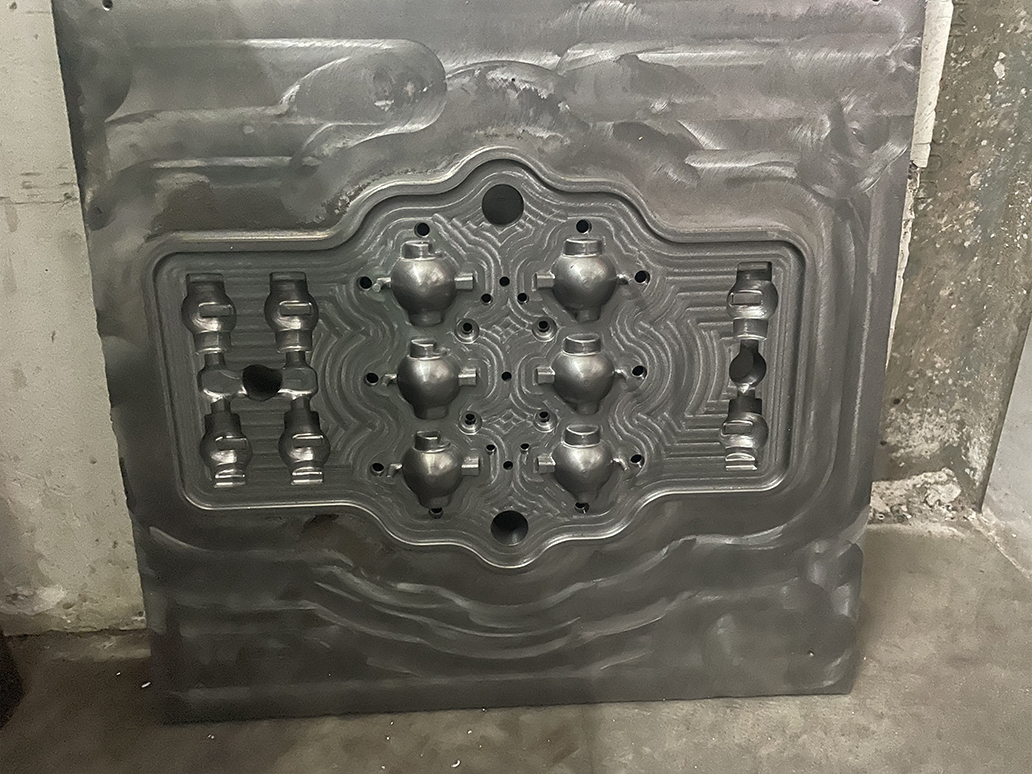

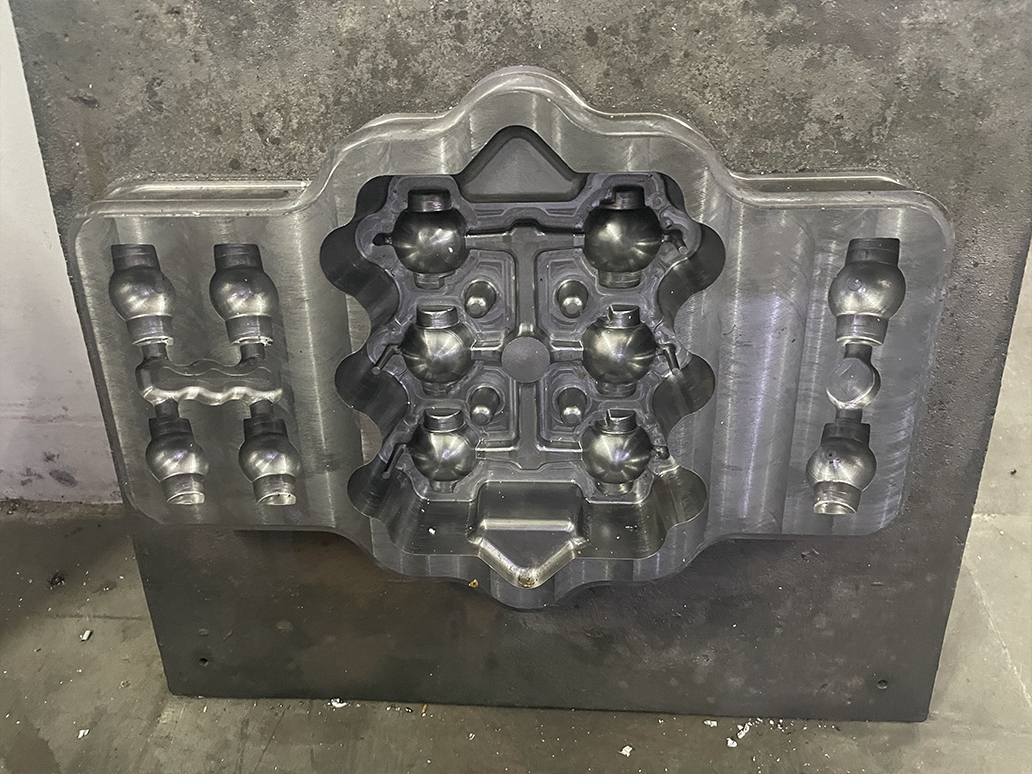

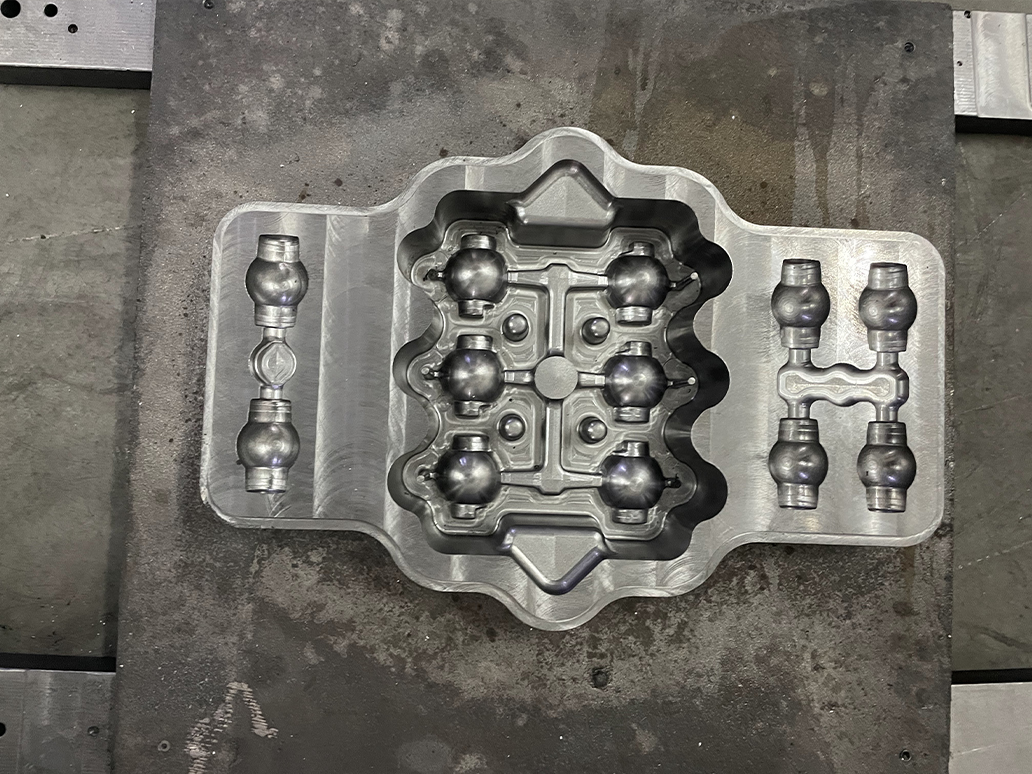

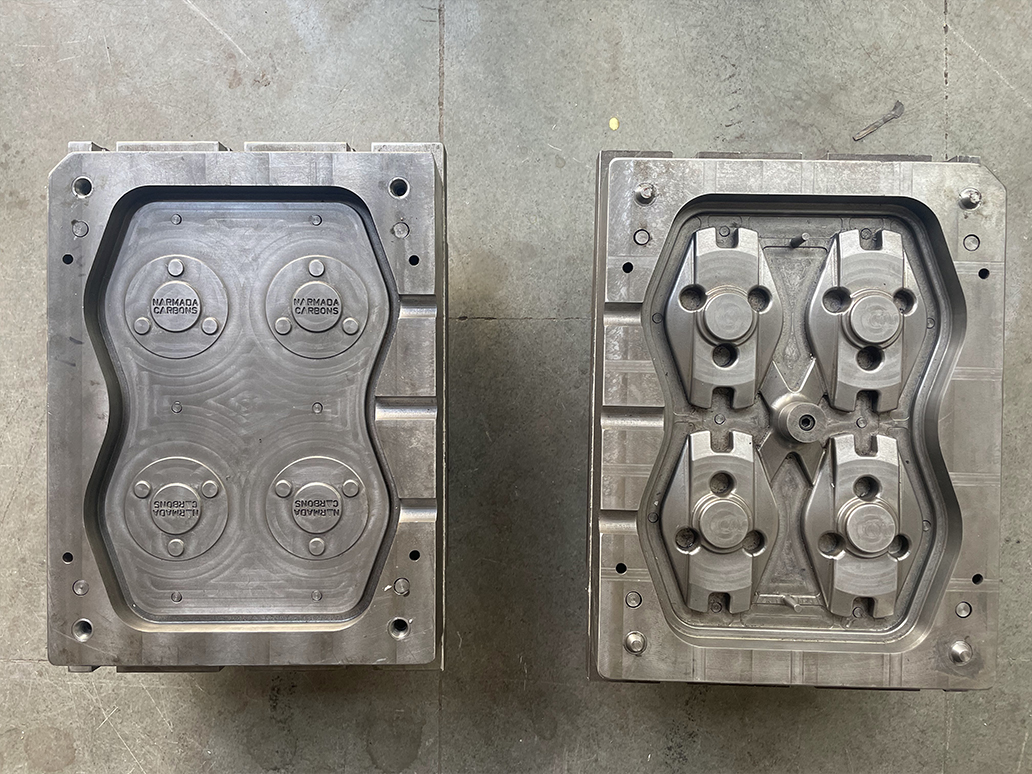

Shell mould die, on the other hand, is a type of die used to create moulds for casting hollow or cored components. The process involves creating a metal die or mould with a cavity in the shape of the desired component. The die is then heated, and a special sand mixture known as shell sand is poured into the cavity. The sand is coated with a thermosetting resin and then heated until it hardens to form a shell. The shell is then removed from the die and used as a mould for casting the component.

Both Shell Core Die And Shell Moulding Die offer several advantages over other types of dies used in the foundry industry. They can produce high-quality, detailed components with complex shapes and dimensions. Additionally, the shell sand used in the process provides a high-quality surface finish, reducing the need for further finishing operations.

Overall, Shell Core Die And Shell Moulding Die are valuable tools in the foundry industry for producing high-quality, hollow or cored components. With their ability to produce complex shapes and high-quality surface finishes, they are a popular choice for many casting applications.